Archive for the ‘Hydroponics’ Category

As Simplicty Controls looks after all the control requirements and channel for Fancyleaf, from time to we are able to offer younger and more cash strapped growers some used equipment at extremely low prices.

Some of the current offerings and prices are in the slide show below. We will have some very cheap channel coming up as we are refurbishing quite a few benches for Salanova production.

One of the most onerous tasks on any hydroponic farm is keeping filtration clean. At Fancyleaf we have 19 recirculating systems, most of which are NFT (nutrient film technique). About half of our growing area is nursery systems which means lots of plant movements. With the amount of ozone we use a floculating effect is generated, which means we have a fair amount of debris to remove from our filters. This used to be a twice a day job, until we changed our standard filters into semi automatic self cleaning filters.

Now the task is much simpler, and the staff are much happier. Instead of turning off the pump, breaking the filter open and washing the screen with high pressure water, they simply walk up to the system, flick on a switch for a 40mm dump valve to open, flick on another switch for 15 seconds to rotate the stainless steel brushes in the filter, then flick both switches off. Less than half a minute and no wet feet from pulling apart filters.

We did this by locating a small 12 volt geared motor and fabricating a stainless steel brush to scrape the debris from the inside of the screen filter. We have plans to develop some electronic circuitry so this job will be done automatically.

Below you will find a series of screen shots to give you an idea of how powerful this application is. Some PLC providers will try to tell you that you can’t run an application like this from a PC, that you must have one of their expensive PLC’s. Well, our experience is exactly the opposite. If you start with a good quality PC then 5 years without failure is not unrealistic, and in fact we have done that with a system at the University of Queensland. The secret is in never turning the PC off, so it is not warming and cooling it’s delicate insides every day. Our PC’s, built for us by Spotty Dog Computer Services, are by no means top end as they don’t need to be, but they are constructed with quality parts. The two units at Fancyleaf live in hot, humid nutrient sheds, and anyone with hydroponic experience will be able to tell you how corrosive this environment is. Yet they perform year in year out with no problem.

Why do we think this is the best channel for growing Fancy lettuce?

A few facts first:

-

We have been very successful in this business for over 22 years in sub tropical Queensland

-

We have consistently been innovators, often supplying other growers with our innovations

-

We have found this the best possible choice for Salanova varieties, because of their growth habit and time in the channel.

-

We have tried most channels on the market and,

-

We know what is needed to be a successful commercial grower

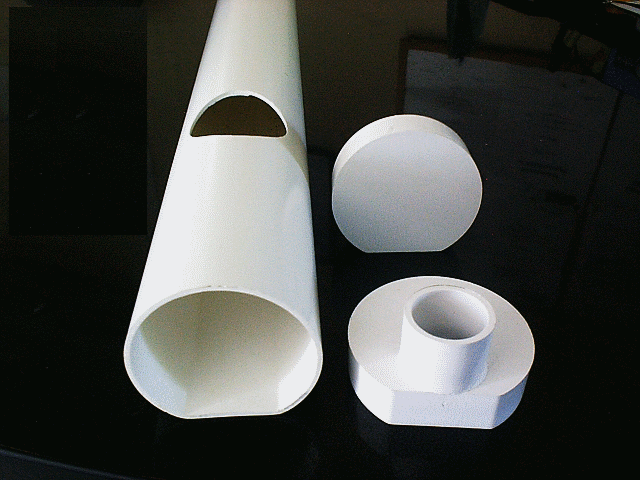

It is no big secret that some of Queensland’s larger growers have been using 65mm round pipe to grow Fancy lettuce for many years, in spite of the fact that the gurus all tell us we must have a flat bottomed channel. We are amongst those growers.

However using this off the shelf product has led to some difficulty, especially for newer growers. We believe there are five main disadvantages to it’s use.

- Contamination. The off the shelf product is manufactured for what is called DWV or drain, waste and vent purposes. As such there is no requirement for food safety in the stabilisers used, which have included such things as lead and tin in the past. These are rarely if ever used now in developed countries, but may still be being used in some places. So there may be a risk of contamination, as has happened in the past.

- Fixing. Being a complete circle, the product is difficult to fix. It is quite dispiriting to come out in the morning and find the outer pipes on each bench turned upside down, when your plants are getting large and crowding each other for space. When you set up your hydroponic business you need to do it properly, once, and not spend half your day doing repairs.

- Nutrient flow. Damming of the nutrient is also another problem using this particular profile. While some growers learn strategies to overcome this problem, others never do. Oxygen is very important to your plant roots and some flat area will certainly assist in oxygenation of the root zone.

- Fittings. Being a product produced for something else, there are no specific fittings to adapt for using the profile for hydroponic growing. This means more expense and time in your setup, which you can do without.

- Holes. It comes without holes. This means considerable time and effort needs to be spent in drilling holes in the profile, which is quite difficult with a round channel as it naturally wants to twist all the time.

A few facts about the Simplicity channel:

-

Windage. Of all the channels we have tried 65mm round pipe seems to be the one least affected by wind, i.e. fewer plants will get blown out during high winds.

-

It is a single use channel. That is, it has been designed for one crop only, to be the best possible channel for that crop, and it does not compromise by trying to be all things to all crops.

-

It will save you money. The amount of plastic in this channel is less than others, therefore the price is lower.

-

It comes pre-drilled with holes at your specified spacings.

-

It is safe as it is manufactured from white, food grade, UV protected PVC using organic stabilisers.

-

It is simple to fix with low cost options and tools. (No special stands to buy or concreting of legs) This will also save you money.

-

No nutrient damming due to the small flat area on the bottom.

-

End caps are available for both ends of the channel, that is all you need to keep your setup costs down.

-

End or centre troughs are easily fabricated or can be supplied